Smart Vision System – AI-Powered Defect Detection Solution

Click Image for Gallery

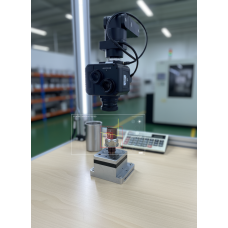

Smart Vision Defect Detection System

Officially Distributed by FA Controls – Malaysia’s Trusted Automation Solution Provider Since 1989

Introducing the AI-Powered Smart Vision Inspection System

Upgrade production quality with the advanced Smart Vision Defect Detection system, powered by cutting-edge AI and deep learning. Precisely detect welding defects including pinholes, incomplete welds, and poor weld quality with real-time automatic inspection enabled by high-speed imaging and industrial-grade computing power.

This solution operates locally with no dependence on internet connectivity, ensuring seamless, secure, and robust performance on your production lines.

Quick Facts at a Glance

| Feature | Specification |

|---|---|

| Inspection Reach | Varies by camera setup (customizable for different production lines) |

| Payload | Industrial PC & Camera System |

| Footprint | Compact setup adaptable to existing lines |

| Weight | System dependent; designed for industrial environments |

Key Features

- 1Deep Learning Algorithms – Achieves high accuracy in defect detection beyond traditional vision methods.

- 2Industrial PC – Robust and reliable computing for demanding factory conditions.

- 3Local Hosting – Operate independently without reliance on internet connectivity for secure and continuous operations.

- 4Vision AI Model – Enables seamless inspection with continuous adaptation and machine learning fine-tuning.

- 5User-Friendly Software Suite – Intuitive interface designed for minimal operator training and fast adoption.

- 6Wide Industrial Applications – Suitable for welding defects, dimensional checks, surface finishing, and thermal conductivity tests.

- 7Multi-Defect Detection – Detects pinhole, offset welds, painting defects, surface cracks, oil marks, and uneven surfaces.

- 8DeepLearn Tool – Empowers users to retrain models to adapt to evolving production requirements and defect types.

- 9Customization Available – Tailor-made solutions for specialized inspection scenarios and unique plant environments.

Business Benefits

- ✔Reduce Manual Inspection Costs – Automate defect detection to cut labor and inspection time.

- ✔Increase Product Quality – Achieve consistent, reliable quality control with AI-driven accuracy.

- ✔Minimize Defect Rates – Early identification of flaws prevents defective products reaching customers.

- ✔Improve Throughput – High-speed image processing accelerates inspection without bottlenecks.

- ✔Enhance Flexibility – Easily retrain AI models for new products and defect types.

- ✔Scalable Deployment – Supports multiple production lines and stations with centralized control.

- ✔Seamless Integration – Works with existing automation and reporting systems.

- ✔Reduce Waste and Recalls – Accurate early detection lowers material wastage and customer returns.

Applications

- Welding Defect Detection (pinhole, incomplete, poor weld)

- Dimensional Inspection and Alignment Checks

- Surface Finish Quality (painting defects, cracks, oil marks)

- Thermal Conductivity Tests for Insulators

- Assembly Line Quality Verification

- Packaging Inspection and Defect Sorting

- Textile and Industrial Fabric Defect Detection

- Electronics Component Inspection

- Automotive Part Surface and Structural Inspection

Comparison Table

| Criteria | Easy Programming | Fast Setup | Flexible Deployment | Safety |

|---|---|---|---|---|

| Smart Vision System | ✔ Icon-driven, minimal coding required | ✔ Quick integration & user-friendly interface | ✔ Supports multiple station setups and scale | ✔ Local hosting enhances data security |

Technical Specifications

| Specification | Details |

|---|---|

| Camera Type | Industrial High-Speed Area or Line Scan Cameras |

| Processing Unit | Industrial-grade PC with AI-optimized hardware |

| AI Model | Deep Learning Vision AI with on-site training capability |

| Connectivity | Ethernet, GigE Switch, Local Network Host |

| Software Interface | User-friendly GUI with model fine-tuning tools |

| Operating Environment | Industrial factory floor, 24/7 operation capable |

| Power Requirements | Standard industrial power supply |

| Customization | Available on request for special applications |

Contact FA Controls

For inquiries, quotations, or technical support:

Email: sales@fa.com.my

Whatsapp: Click link above

Email: sales@fa.com.my

Whatsapp: Click link above