Smart Vision Counting System – AI-Powered Solution

Click Image for Gallery

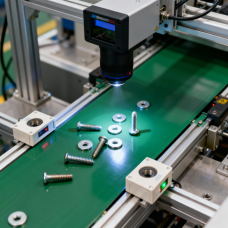

Smart Vision Counting System

Real-Time Multi-Product Counting with Superior Accuracy and Integration

The Smart Vision Counting System empowers manufacturers to detect, differentiate, and count diverse products on a single conveyor in real time. Designed for seamless integration, this compact solution ensures unmatched speed, precision, and scalability for modern factories.

Quick Facts

| Feature | Specification |

|---|---|

| Counting Speed | High-speed real-time (per conveyor cycle) |

| Object Types | Multiple product types simultaneously |

| Footprint | Compact, easy to integrate |

| Accuracy | Near 100% precision |

Key Features

- Multi-Product Detection – Count different product types within a single conveyor view in real time.

- High-Speed Processing – Handles fast conveyor operations with zero disruption.

- Error Elimination – Achieve near 100% accuracy by eliminating manual errors.

- Quick Deployment – No dataset labeling required, enabling faster setup.

- Compact Design – Easily fits into existing factory footprints.

- Adaptive Functionality – Continuously adapts to new product designs and changes.

- Seamless Connectivity – Compatible with PLC, MES, and SCADA systems.

- Low Maintenance – Optimized durability with minimal upkeep required.

- Scalable Solution – Supports higher workloads as production grows.

Business Benefits

- Reduce costly manual errors.

- Boost efficiency and throughput across production lines.

- Achieve consistent quality compliance with real-time monitoring.

- Minimize downtime caused by miscounting issues.

- Enable business scalability without increasing manpower.

- Improve flexibility to handle product variations.

- Fast return on investment with rapid deployment.

- Future-proof your operations with adaptive vision technology.

Applications

- Automotive assembly lines

- Electronics manufacturing

- Consumer appliance production

- Industrial equipment assembly

- Food & beverage packaging

- Pharmaceuticals counting and sorting

- Small parts inspection

- Fastener and screw manufacturing

- High-volume packaging lines

Comparison

| Feature | Traditional Counting | Smart Vision Counting System |

|---|---|---|

| Easy Programming | Manual setup required | Automatic, intuitive setup |

| Fast Setup | Time-consuming | Plug-and-play |

| Flexible Deployment | Product-specific | Multi-product recognition |

| Safety & Reliability | Prone to human error | Error-free automated monitoring |

Technical Specifications

| Specification | Details |

|---|---|

| Detection Type | Vision-based recognition |

| Response Time | Millisecond-level real-time operation |

| Supported Items | Multiple product types in single view |

| Accuracy Rate | Up to 99.9% |

| Integration | PLC, MES, SCADA-compatible |

| Operating Mode | Continuous monitoring |

| Setup Process | Quick deployment, no labeling required |

| Hardware Footprint | Compact, minimal space needed |

| Connectivity | Ethernet & industrial protocols |

| Maintenance | Low-maintenance with self-optimizing software |

Contact FA Controls

FA Controls – Official Distributor